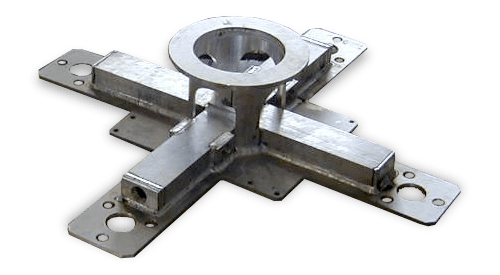

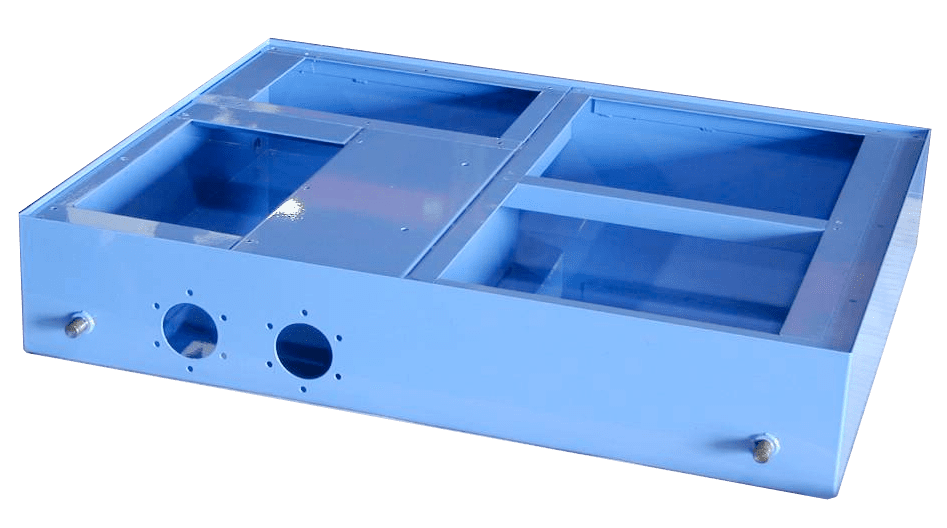

Punched Metal Components

for Weldments and Fabrications

CNC punching is an important option for generating sheet metal blanks. Punching is an inherently faster operation that lends itself to metal fabrications that have many similar features or where there is a higher volume of parts per run.

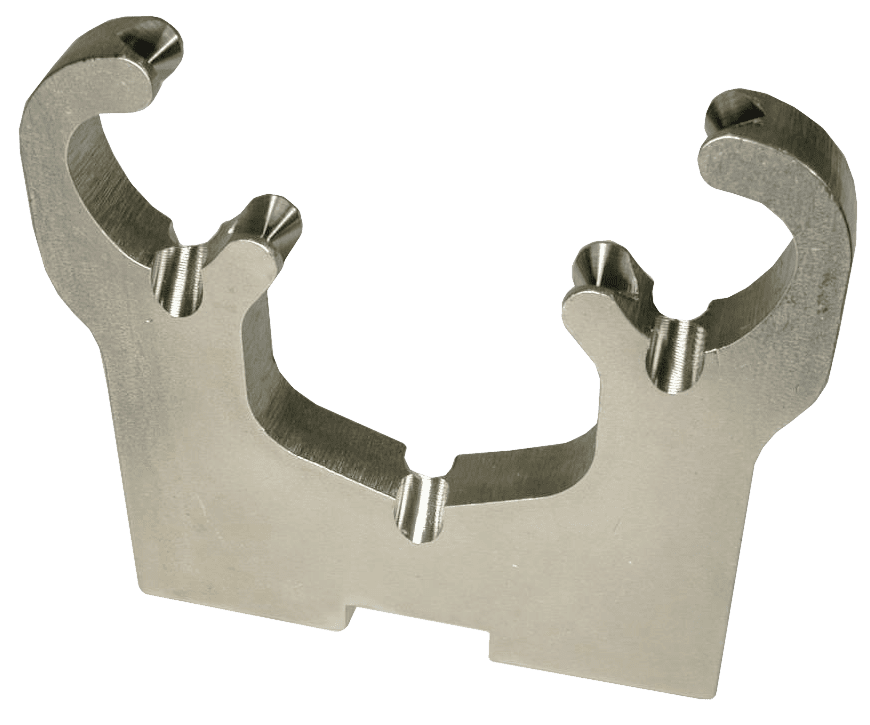

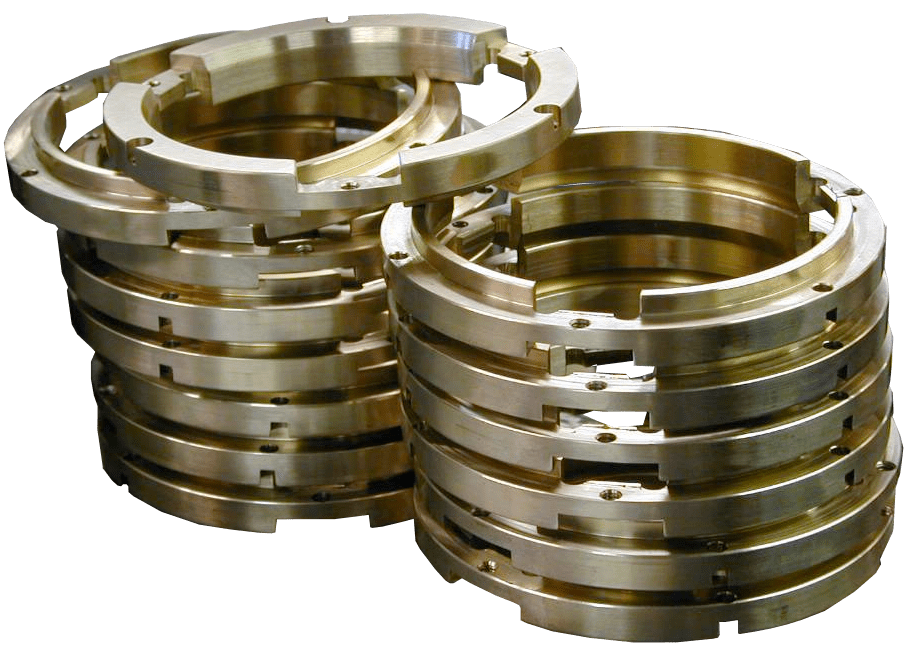

Stainless specialists

Specialists in punching and stamping stainless steel and mild steel parts manufacturing.

One-stop machine shop

Single, reliable source for high-quality parts. Comprehensive in-house capabilities.

Precision parts fabrication

Experienced craftsmanship using advanced technologies.

Fast Lead Times

Quick, accurate parts turn-around through flexible scheduling

Engineering solutions

Partnering to provide the best solution for your part design.

For higher volume metal parts and assembly components, punching and stamping save time and with the high precision of our equipment, will assist in producing accurate and high-tolerance parts. High strength is possible in thin parts that can have complex shapes. Economy of scale and volume at an economical cost is the primary reason for metal punching.

Thorough Process and Procedure Documentation

We want to be your manufacturing partner rather than just a parts supplier. To remain competitive in a global market, our customers are looking for partners that offer services above and beyond. All processes and procedures are documented.

0+

Years in business

0+

Current Customers

0+

Active Part Numbers

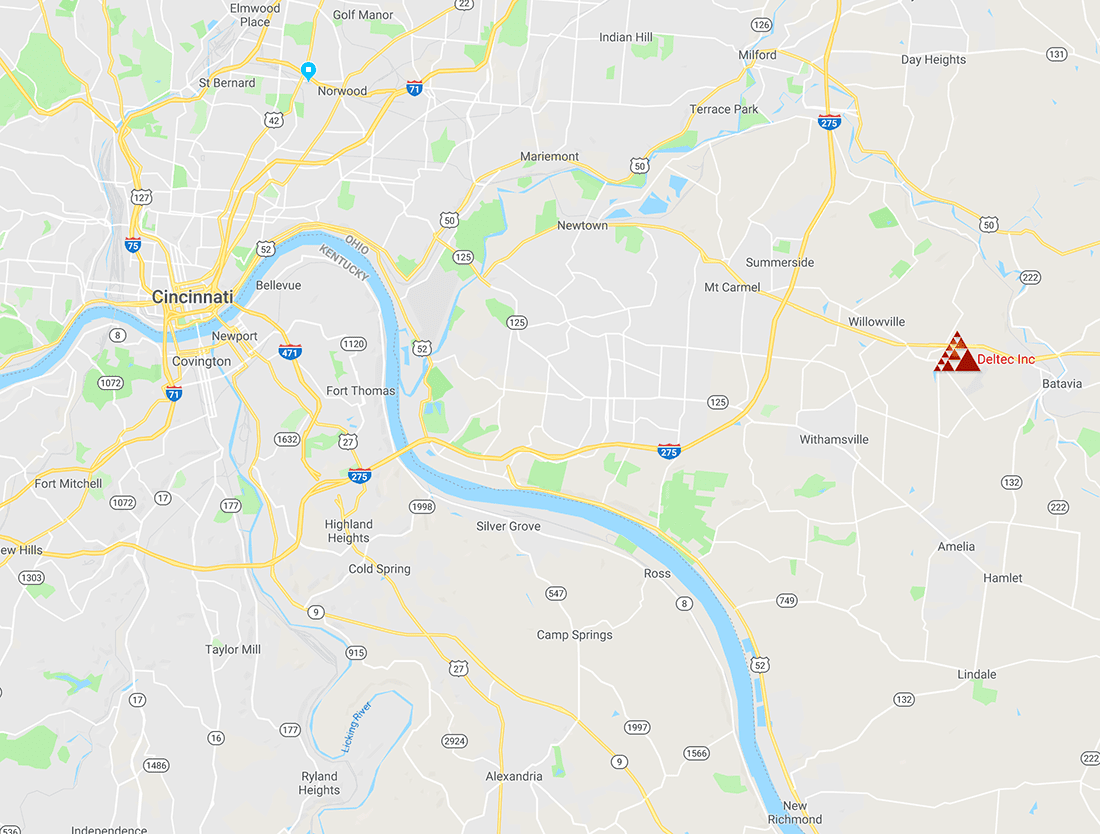

Greater Cincinnati location

4230 Grissom Drive

Batavia, OH 45103

U.S.A.

Batavia, OH 45103

U.S.A.

Give us a call

(513) 732-0800

Contact us by email

Your form submission will be read immediately by Deltec Manufacturing Engineers.